PDF - 9Mo - Grande Dixence SA

PDF - 9Mo - Grande Dixence SA

PDF - 9Mo - Grande Dixence SA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

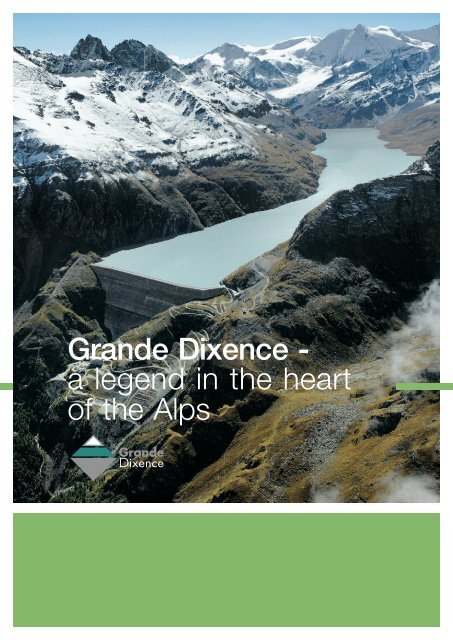

<strong>Grande</strong> <strong>Dixence</strong> -a legend in the heartof the Alps

GD. P.2

GD. P.3SummaryEpic construction of the dams3000 men to tame the power of the glaciersLogistics of a campaign armyTypes of damAn underground arterial systemThe highest wall in the worldA real challenge: spot height 2400Z’Mutt pumping stationStafel pumping stationFerpècle pumping stationArolla pumping stationThe real challenge: managing the waterSafetyPower plantsFionnay power plantNendaz power plantCleuson-<strong>Dixence</strong> complexThe accidentThe challenges of hydropowerA sense of balanceThe environment: a constant concernFinancial participations and shareholdersof <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>P.10P.15P.18P.21P.22P.29P.32P.35P.37P.38P.41P.42P.48P.50P.52P.54P.56P.59P.60P.62P.68P.70

GD. P.4<strong>Grande</strong> <strong>Dixence</strong>Water tamed

GD. P.5

GD. P.6

GD. P.7

GD. P.8Constructionfrom then until now

GD. P.9

GD. P.10Epic constructionof the damsWater tells a taleWater…The primeval element without which there can be no life.Water…Silent, tranquil, asleep in Lake Dix.Water…Wild and turbulent, raging through the turbines.Water…An inexhaustible source of energy.Valais Canton possesses the most beautiful, the mostinestimable of riches: white gold! With its 900 km 2 ofeternal snows, it is Switzerland’s water tower. A preciousreservoir of life and energy in the heart of Europe.Thanks to its altitude and Alpine foothills, more thantwo thirds of the rainfall is kept in solid form over thewinter. When spring and summer come, snow and icebecome liquid.People have always attempted to domesticate the bubbling,vital flow. They have battled against water andits outbursts. But above all, they have fought for waterand the blessings it brings. Valais Canton has witnessedthese struggles throughout its history: thepainstaking work of raising dykes along the river Rhônein order to bring it under control; the extraordinary networkof 200 “bisses” or canals that collect essentialwater for pasture and rye crops from the valley head;the ingenious system for irrigating the vines.Closer to us in time, the last century saw the epic constructionof the dams, the titanic struggle deep in themountains to catch and store the most incredible formof energy: hydroelectricity. Today, thanks to the dams,Valais Canton generates 10 billion kWh of this clean,renewable and environmentally-friendly energy.One of the outstanding episodes in the conquest ofthis “white coal” was without a doubt the building ofthe <strong>Grande</strong> <strong>Dixence</strong> complex. This scheme, worthy ofthe Pharaohs of ancient Egypt, is the jewel in the crowncreated by human ingenuity and courage to harnessthe potential of a unique glacial basin covering 350 km 2 .Immediately after the Second World War, Switzerlandneeded energy to develop its industries. In 1945, theSwiss Federal Water Department took stock of thecountry’s hydropower potential. When the expertsanalysed the possibilities of the Rhône basin, they concludedthat there were still some valleys that couldprofitably be developed.

GD. P.111951: Construction works start at <strong>Grande</strong> <strong>Dixence</strong>to collect water from the Viège (Matter Valley) andthe Borgne (Hérens Valley) rivers. The first <strong>Dixence</strong>dam, built barely 15 years before, is to be submergedin the new lake, engulfed by a constructionsite on an absolutely record scale.1965: The <strong>Grande</strong> <strong>Dixence</strong> scheme is operational.It has taken around 15 years of unremitting workand 3000 men labouring tirelessly in shifts to realisethis dream of modern times… an invertedpyramid, an inexhaustible source of energy.Stafel, construction of the afterbay reservoir

GD. P.12First <strong>Dixence</strong> dam and outline of the future <strong>Grande</strong> <strong>Dixence</strong> schemeDix Valley soon became accepted as the site with thegreatest potential for development. This high mountainvalley had all the geological and topographical conditionsthat made it ideal for conversion to a giantreservoir. No built-up area would be affected, the onlyagricultural land was high altitude pasture and, aboveall, the predicted storage capacity was enormous: 400million m 3 .These two achievements engaged more than 3000men in a struggle that lasted through to the beginningof the 1960s. A bold avant-garde project thattoday contributes to the well-being of the whole community.Geologists, hydrologists, surveyors and engineers tackledthe solving of two major problems. First, how toenlarge the existing lake with the <strong>Dixence</strong> complex builtsome 15 years before. Second, how to create collectingworks capable of gathering water from the neighbouringMatter, Ferpècle and Arolla valleys.

GD. P.13Le Chargeur, fabrication of concrete wall block Nendaz power plant, excavation, 1957

GD. P.14Le Chargeur, excavating the dam, 1956

GD. P.153000 men totame the powerof the glaciersA superlative construction projectThe <strong>Grande</strong> <strong>Dixence</strong> scheme, the building project ofthe last century, to which every superlative applies, isa tremendous source of power. In its own way, it is alsoa monument to the glory of human ingenuity. This concretetemple enthroned in a mineral universe wouldnever have been possible without the vision, intelligence,determination and courage of human beings.Geologists, hydrologists, surveyors, engineers, guides,skilled and unskilled labourers… more than 3000 individualsfighting to tame the power of the glaciers. Incold or stormy weather, in the snow or under a blazingsun, they joined together to complete the biggestgravity dam in the world.To say that working high in the mountains is difficult isan understatement. The cold and storms at an altitudeof 2400 m have to be experienced fully to understandhow the lungs burn, how the joints tear. The snow andthe blazing sun must have been met head-on truly tofeel how the skin freezes and withers, how the lipsburst. How the body collapses with the pain and fatigue,the spirit cursing the water seeping everywhere…Fionnay-Nendaz, the day before the tunnels were joinedFrom the beginning, those in charge of the project knewthat they would have to cope with difficult living conditions.The question was how to manage such a largepool of labour on a high-altitude building site. At itspeak, in October 1954, 1600 men - from Valais Canton,from the rest of Switzerland and from Italy - were workingtogether on the <strong>Grande</strong> <strong>Dixence</strong> site.

GD. P.16

GD. P.17The pace of work was intense: 11 hours of labour byday and 10 hours at night. But everything possible wasdone to reduce the hardships on site, and make thegeneral environment as pleasant as possible. The accommodationwas completely different from the temporaryhuts of construction sites at the time. Duringthe winter of 1953-1954, an imposing building wasconstructed from prefabricated blocks. The workersnicknamed it the Ritz! The Ritz hotel and restaurant stillwelcomes visitors and ramblers today at the foot ofthe dam.Thanks to these excellent arrangements, the accidentrate was extremely low for a site on such a scale.Unfortunately, despite every precaution, it was not possibleto avoid tragedy completely. The most seriousaccidental injuries were caused by the collapse of theCheilon tunnel calotte and by an avalanche on 16February 1961 that killed three guides on guard duty.The dam was completed on 22 September 1961…3 years ahead of time. Some 500 million Swiss francswere paid out in wages over 11 years.A social service, entertainment, a weekly film show, alibrary, and games rooms were provided for the workforce.But the men did not simply wait for everythingto be offered to them on a plate. They got organized,established a brass band, a gymnastic society, choirs,football teams. Every winter, they organized a ski race:the Miners’ Trophy.Fionnay-Nendaz tunnel, mine-blasting, 1958 Le Chargeur gallery, vibration of concrete, 1955

GD. P.18Pralong-Blava, cement cableway, 1954Logisticsof a campaign armyA mountain of concreteCasting a mountain of concrete in the depths of theDix Valley took the courage and skill of thousands ofmen. But over and above the work effort, a networkto supply the construction materials had to be thoughtof, designed and constructed. Without the logisticsof a campaign army, there would be no regular deliveriesof gravel, cement, concrete…The success of the <strong>Grande</strong> <strong>Dixence</strong> construction projectwas due in large measure to that uninterruptedsupply of materials, which enabled the pace of thework to be maintained night and day. The vital rawmaterial for the dam was quarried from the Prafleurimoraine, at above 2600 m altitude. The rock wascrushed into gravel on the spot. Endlessly long undergroundconveyor belts then carried the gravel tothe Blava concrete plant.The dam alone required 1.3 million tonnes of cement- a figure impossible to visualise. To give an idea, nofewer than 9 cement works in Switzerland were keptworking flat out for years to achieve this output.Special wagons were ordered to carry everythingby rail. Cableways, purpose designed, then transportedthe cement in 400 kg canisters. And all at apretty pace: 200 tonnes an hour!Ropeways spanned the void between the sides ofDix Valley and carried the buckets to whichever partof the dam was currently being built. These ropewayswere very strong and able to carry up to 20 tonnes.But above all, whatever the weather conditions, atnight, in fog, snow or rain, they enabled the concreteto be deposited with remarkable accuracy. Althoughthe sloping sides of the valley are more than 700 metresapart, the tolerance margin was only... 50 cm!

GD. P.19Ropeway shuttle

GD. P.20Ferpècle arch dam<strong>Grande</strong> <strong>Dixence</strong> gravity dam

GD. P.21Typesof damGravity dam<strong>Grande</strong> <strong>Dixence</strong> is a typical gravity dam. It is essentiallya triangular body with an extremely broad basewhich gets narrower towards the top. Its own weight(15 million tonnes in the case of <strong>Grande</strong> <strong>Dixence</strong>) isenough to resist the water pressure.There is also a variation of this design: the gravity-archdam. This type of storage dam gets its stability bothfrom its own weight and from the transferral of the waterpressure to the valley sides (e.g. Schlundbach damin Lucerne Canton).Gravity damArch damIn contrast to the gravity dam, which is often a massivelyheavy construction, the concrete arch dam is particularlyelegant. But the decision to build this type ofdam depends on many factors: the shape of the valley,the lie of the land, the materials locally available …The arch dam’s main characteristic is clean lines givingan impression of lightness. Rather than fighting theweight of the water head on, the arch transfers boththe vertical and horizontal stresses to the valley sides.The Z’Mutt dam, at the foot of the Matterhorn is a perfectexample.Arch damEmbankment damThe principle of the embankment dam is straightforward- a certain amount of material is gathered togetherin order to hold back the water. Generally, at the centreof the dam there is a completely watertight core.It is reinforced both upstream and downstream bybackfilling and piles of rock.In contrast to the other types of concrete dam, the embankmentdam has a cross-section that is much widerthan it is high (e.g. Mattmark dam in Valais Canton).Embankment dam

GD. P.22An undergroundarterial systemThe tunnelling of the mountainThe building of the <strong>Grande</strong> <strong>Dixence</strong> dam is itself apharaonic achievement. But impressive as the sightof that gigantic wall is, it is only the tip of the iceberg.What was unique about the project was not the challengeof building a wall capable of retaining an artificiallake, however vast. The particular feature of<strong>Grande</strong> <strong>Dixence</strong>, the spark of genius produced by itsdesign engineers, is that it is able to collect water from35 glaciers in Valais Canton, from the Zermatt to theHérens valleys. And this great feat has been madeinvisible, hidden away, safe from the weather. Deepin the entrails of the mountain, at the very heart ofthese peaks and valleys.In order to bring all this water to Dix Valley, men hadto survey the rock in every detail. They probed it,sounded its seismic activity and examined its geologybefore drilling and tunnelling into it. There wereenormous constraints associated with the creationof these vital collecting works that are just like the arterialsystem of the human body. And one key figurewas always at the forefront of everyone’s mind: 2‰!An obsession with this number made the engineeringteams, the physicists, the surveyors and thegeographers, who worked in turn on the route to betaken by the future main water conduit, suffer mostdreadfully.2‰ was the gradient that had to be achieved throughout.It was the constraint that simply had to be respectedin plotting the route to be taken by the watercollecting works.At the arrival point, the challenge had been met beyondevery expectation. Around 100 kilometres of tunnellingcriss-cross the mountain. 75 water intakes feedthe tunnels. 4 pumping stations are needed to routesome of the water. The need for pumping stations maycome as a surprise. But a particular feature of the<strong>Grande</strong> <strong>Dixence</strong> complex is that certain major glaciers- Ferpècle, Arolla, Z’Mutt and Gorner for example - areat a lower level than the main water conduit which isat a spot height of 2400 metres. The water must thereforebe pumped up to the required altitude in the collectorthat forms a real underground river, parallel tothe Rhône.The laborious civil engineering works lasted 15 years.At the 23 high-altitude building sites studding the valleys,every centimetre of tunnel had to be hacked outof the rock. And with this kind of work, it is impossibleto move faster than technology allows. The dimensionsof the front leading the attack cannot be changed.There is no point in increasing teams or doubling upmachinery.

GD. P.23Nendaz power plant, excavation, 1957

GD. P.24Ferpècle, P2-P3 tunnel, 1951Le Chargeur, excavation of the <strong>Dixence</strong> canyon, 1954 Nendaz power plant, tunnel, 1957

GD. P.25Working conditions on the dam were harsh. And sowere conditions at the sites where the collecting workswere being constructed. Living conditions inevitablysuffered from the rigours of high altitude, the risks ofavalanche and rockfalls and the discomfort of tunnelworking. In the heroic mythology of great constructionprojects, the driving of the Bricola, P4 (Arolla collector)and Stafel tunnels occupy prime positions.In the valleys of Valais Canton, old folk still talk aboutMellichen and the Alphubel, inhospitable places wherefood had to be brought in by helicopter in the winter andwhere two hundred and fifty men were attacking themountain simultaneously on ten fronts. They also rememberthe Stafel siphon where the supporting beamssplit as though they were matches. A tunnel where it wasimpossible to move forward more than 50 centimetreswithout being forced to shore up the roof…Of course, the bonuses, a feature always associatedwith mining work, were a motivation for the men whoformed the rock assault force. But to be a good miner,it was still a question of showing yourself to be a hardworker, capable of boldness and tenacity. The mountainpeople of the Valais, who formed the majority ofthese elite troops, prided themselves on having thesequalities. The drilling teams often comprised peoplefrom the same region, and even the same valley. Theywere a particularly sought after labour force that laterwent on to drive the Swiss motorway tunnels.

GD. P.26<strong>Grande</strong> <strong>Dixence</strong>today

GD. P.27

GD. P.28

GD. P.29The highest wallin the world!A record-breaking damHalf a century has passed since human endeavour builtthe <strong>Grande</strong> <strong>Dixence</strong> dam. And fifty years later, the wallnestling between the flanks of the Dix Valley remainsunique. At 285 metres, it is still the highest wall in theworld!In order to be able to contain the more than 400 million m 3of water stored each year (a volume equal to 8000years of the Valais grape harvest for example), the<strong>Grande</strong> <strong>Dixence</strong> gravity dam has beaten many records.No fewer than 6 million m 3 of concrete were pouredbetween the mountains: a wall 1.5 metre high and 10cm wide could be built around the equator with thatvolume of concrete. At its base, the dam is two hundredmetres thick (equal to the length of two footballpitches). At the top - in technical terms the crest of thedam - it narrows to a ribbon of only… 15 metres.To make the soil foundation watertight, the grout curtainsurrounding the dam goes down 200 metres intothe gneiss and granite of the surrounding mountainmass. It extends 100 m into each valley bank. The wallitself is made up of 16 m x 16 m concrete blocks jointedtogether in a way that ensures maximum cohesion,strength and impermeability.Visitors entering the <strong>Grande</strong> <strong>Dixence</strong> cavern on footare always surprised by the bottomless shafts thatallow the structure to be monitored. Stretched by 150kilo counterweights, seven pendulums plunge silentlyacross the full depth of the wall. They measure deformationin the retaining wall continuously. This systemallows the movements of the dam to be checked toan accuracy of 5 hundredths of a millimeter.Because the concrete monster breathes! This 15-million-tonnegravity dam, this colossus that is heavier thanthe Great Pyramid of Cheops is sensitive to change.Depending on whether its stomach - its lake - is fullor empty, the crest moves 11 centimetres downstreamor back to its initial position.Apparently peaceful, Lake Dix is surging energy domesticatedby man. 3.65 km 2 in area (for comparison,the area of Lake Joux, in Vaud canton, is 9.5 km 2 ), itis 5.3 km long and has a maximum depth of 227 metres.This energy reserve enables enough electricity tobe supplied throughout the year to meet the needs ofa region of around 400,000 households.

GD. P.30400 million m 3of water

GD. P.31

GD. P.32A real challenge:spot height 2400Water collecting worksThe <strong>Grande</strong> <strong>Dixence</strong> dam is a gigantic stopper andLake Dix, an artificial lake, is an energy storage unit.These feats of human ingenuity were placed strategicallyat the heart of a 357 km 2 catchment area, half ofwhich is covered by 35 glaciers. But a way still had tobe found of catching and collecting all the liquid goldslipping between the rocks.An immense system of collecting works and undergroundcanals was designed and driven through themountain. Again, the numbers make the head spin. Inorder to collect the water that flows between theMischabel and Mont-Blanc de Cheilon mountains, approximately100 kilometres of tunnel had to be dug,including a 24-kilometre main water conduit at 2400metres altitude. No fewer than 75 water intakes studthe 35 glaciers and supply <strong>Grande</strong> <strong>Dixence</strong> with itsprecious raw material.Logically, one would think the water would be broughtto dam level simply by gravity, flowing gently along themountainside to the retaining point. But that means acatching point above the <strong>Grande</strong> <strong>Dixence</strong> dam. In fact,this is not always the case. Scarcely 40% of the waterfilling Lake Dix reaches it by following the natural gradient.So how could water be collected at 2400 metres,the altitude at which the main water conduit feedsinto the reservoir? How could this challenge be metsuccessfully when the largest glaciers in the area havea melting zone below that essential spot height?The high altitude of the dam forced the design engineersto demonstrate their ingenuity. In order to driveback the waters of the Gorner at the foot of Mont-Rose,from Stafel at the foot of the Matterhorn, from Ferpècleat the foot of Dent-Blanche, and from Arolla at the footof Mont Collon, there was only one option: pumping.4 stations with a total capacity of 186 MW (equivalentto the power of about 35 locomotives) were built fromscratch.Altogether, these pumping stations deliver a total volumeof 300 million m 3 of water to the main water conduit,at the same time consuming 380 million kWh ofenergy, mainly at times of low energy demand.Thanks to this clever arrangement, the energy potentialof this Swiss Alpine region has been fully realized.By gathering as much water as possible in Lake Dix,either by natural flow or by pumping from neighbouringvalleys, the water of an entire region can be exploitedin the form of peak energy, its prime asset being itsflexibility.

GD. P.33VIEGERIVERSTAFELSTATIONALT: 2180 MZ'MUTTSTATIONALT: 1900 MAROLLASTATIONALT: 2009 MFIONNAYPOWER PLANT(290 MW) ALT: 1486 MFERPÈCLESTATIONALT: 1835 MGRANDE DIXENCE(400'000'000 M 3 )ALT: 2364 MPRINTZERIVERBORGNERIVERCLEUSON(19'500'000 M 3 )ALT: 2186 MCHANDOLINEPOWER PLANT(150 MW) ALT: 493.5 MRHONE RIVERBIEUDRONPOWER PLANT(1200 MW) ALT: 481 MNENDAZPOWER PLANT(390 MW) ALT: 479 MGRANDE DIXENCE(400’000’000 M 3 )ALT: 2364 MPRINTZERIVERDams2500m2000m1500mAL Z’MUTTSTATIONALT: 1900 MSTAFELSTATIONALT: 2180 MFERPéCLESTATIONALT: 1835 MAROLLASTATIONALT: 2009 MCLEUSON(19’500’000 M 3 )ALT: 2186 MFIONNAYPOWER PLANT(290 MW) ALT: 1486 MPumping stationsand power plantsPressure shaftsHeadrace tunnelsMain water conduit1000mCHANDOLINEPOWER PLANT(150 MW) ALT: 493.5 MRiver500m0mRHONERIVERNENDAZPOWER PLANT(390 MW) ALT: 479 MBIEUDRONPOWER PLANT(1200 MW) ALT: 481 M

GD. P.34Z’Mutt afterbay reservoir

GD. P.35Z’Muttpumping stationBeauty spotAt the bottom of the Mattertal valley, clinging to the lastAlpine pastures, a few elegant ‘mayens’ are evidenceof the hamlet of Z’Mutt. In this beautiful and peacefulspot, the <strong>Grande</strong> <strong>Dixence</strong> engineers were determinedto show respect for nature and harmony. As far as possible,the concrete invasion was kept within limits. Theonly major visible section is the dam that blocks thegorge. Yet, despite its height of 74 metres, the slim andelegant arch dam blends discreetly into the landscape.Apart from the service building, all other facilities (sandand gravel traps and pumping station) are belowground.Here in this wild enchanting place, water is gatheredfrom the Bis and Schali glaciers that overhang the Viègeand from the Gorner. Some experience was neededbefore the Gorner was brought under control. Everysummer in fact, the sudden emptying of a glacial pocketthreatens to submerge everything.4 pumps with a total capacity of 88 MW are used atZ’Mutt to deliver 140 million m 3 of water each season.They are driven through a penstock, an inclined steellinedshaft that brings the water from 1900 metresaltitude to the Trift tunnel at 2400 metres altitude or thelevel of the main water conduit.7N64221 Arch dam, height 74 m852345Afterbay reservoir, useful volume 700,000 m 3Water intake and headrace tunnel, ø 2.30 mDischarge shaft to main water conduit, ø 1.80 to 1.90 mSchali-Bis steel-lined shaft, ø 1,35 m142 3 1215119 1619917180 50 100m2112H13 2011106 Bodmen underground afterbay reservoir, useful volume 2500 m 37 Schali-Bis headrace tunnel, discharge rate 8.5 m 3 /sec.8 Bodmen spillway tunnel9 Gornera headrace tunnel, discharge rate 25 m 3 /sec.10 Service and control building11 Operating cableway12 Access gallery to power plant13 Drainage tunnel14 Dam access tunnel15 Emptying of afterbay reservoir and return to Z’Mutt stream16 Cable gallery17 Switchyard18 130 kV line19 Roads and road tunnel20 Z’Mutt-Schönbühl path21 Heliport22 To 12 MW plant in Mutt (EWZ)Cross-section of station2 units each comprising:1 pump delivering 5.5 m 3 /sec., head 470 m, and1 synchromotor, 30 MW2 units each comprising:1 pump delivering 3.2 m 3 /sec., head 65 m, and 1 synchromotor,14 MWTotal pumping station discharge rate: 17.4 m 3 /sec.123456789Low pressure control valveInternal servicesTransformerCable galleryOverhead travelling craneMachine hallMotorPumpHigh pressure control valve4536278910 5 10m

GD. P.36Stafel water settlement zone

GD. P.37Stafelpumping stationAt the foot of the MatterhornWith its cold mineral colours, this is a unique landscape,breathtaking in its beauty and solitude. Standing solidlyat the foot of the renowned north face of the Matterhorn,Stafel is a terminal moraine of the Z’Mutt glacier.The only features betraying the presence of humansare two large sand traps and an afterbay reservoir retainedby an embankment, which supply the pumpingstation. Water from the Z’Mutt glacier is stored here,in this windy, silent place. The water joins that suppliedby the Mischabel, Findelen, Obertheodul and Furggglaciers which cross the dip in the valley via the Stafelsiphon.The pumping station drives the water from the glacierinto the bend of the siphon to force it up to the collectinglevel some 250 m above. Year in year out, Stafelpumps an average of 100 million m 3 of water.N12101121014 9H3 7458611512345678910111213141516ImpoundmentsWater intakeFlood gateTwo sand traps, each 7.5 m 3 /sec.Sand trap flushing tunnelReservoir feed canalWinter headrace canalReservoir drawoff and spillway tunnelSuction conduit, ø 1.80 m, discharge rate 9.9 m 3 /sec.Torrent bedsAqueduct crossing under torrentsRoad130 kV line and switchyardHeliportAfterbay reservoir, useful volume 70,000 m 3Pumping station16111311Cross-section of station3 units each comprising:1 pump delivering 3,3 m 3 /sec.,head 212 m, and 1 synchromotor, 9 MWTotal station discharge rate: 9.9 m 3 /sec.123456789Suction conduit, ø 1.80 m, discharge rate 9.9 m 3 /sec.SwitchgearOverhead travelling craneTransformerHigh-pressure pumpValveMotorDischargeBuried aqueduct32 4 5179680 5 10m

GD. P.38FerpèclepumpingstationUnpredictable ragesAt Ferpècle, only a small 100 thousand m 3 cubic metredam and a sand trap, anchored to the rock and setamidst larches, are visible. That is all the eye can see.The genius of the <strong>Grande</strong> <strong>Dixence</strong> engineers knowshow to be discreet. The power plant has been able tolose itself, hidden beneath the mountain again like theone at Z’Mutt.This is a dangerous area. The Mount Miné and Ferpècleglaciers are unpredictable. If the mountain-dwellers areto be believed, these glaciers have a reputation for beinghot-tempered. On several occasions in the past,the break up of the ice has been violent and turbulent.To prevent a similar natural disaster from damaging thepumping station at Ferpècle, there is also an accesslimiter on the water intake sand trap. This clever deviceprevents excessively high flood water from enteringthe works.Each year, the Ferpècle pumps drive 63 million m 3 ofwater towards the neighbouring Arolla valley andanother pumping station, via the Maya reservoir, whichis also hidden in the mountain.1234567891011121314151617ForebayWater intakeTwo sand traps, total discharge rate 11 m 3 /sec.Arch dam, height 25.5 mFlood relief worksOverflow weirReservoir drawoff and spillway tunnelSuction conduit, ø 1.90 to 1.55 mDischarge shaft, ø 1.55 to 1.90 mPower plant drainage tunnelPower plant access bridge and tunnelRoadService building with power plant access shaftSwitchyard130 kV lineHeliportAccommodation132 50 50 100m18586 471719 91314 11151216H1011N1819Afterbay reservoir, useful volume 100,000 m 3Pumping station12345678910Suction conduit, ø 1.90 to 1.55 mLow pressure control valve5 kV busbars130 kV cablesOverhead travelling craneMachine hallTransformerPumpHigh pressure control valveDischarge shaft, ø 1.55 to 1.90 mCross-section of station3 units each comprising:1 pump delivering 2.8 m 3 /sec, head 212 m,and 1 synchromotor, 7.1 MWTotal station discharge rate: 8.4 m 3 /sec.4 53612789100 5 10m

GD. P.39Ferpècle afterbay reservoir

GD. P.40Bertol Lower water intake

GD. P.41Arollapumping stationA high valley that is not… high enoughAt the end of the water collecting works, the high Arollavalley is still… too low. It is more than 300 m away fromthe crucial spot height of 2400 and the main water conduitleading to Lake Dix.Arolla receives the water already pumped by Ferpècleand adds the water contributed by the Tsidjiore Nouveand Bertol glaciers. Altogether, the pumping station atArolla catches and discharges 90 million m 3 of water.It is the most powerful pumping station in the schemeafter the one at Z’Mutt. Three double suction pumpseach with a capacity of 16.2 MW discharge their 4.2 m 3per second at a head of 312 m.12345678910111213141516Ferpècle headrace tunnel, discharge rate 8.4 m 3 /sec.Bertol Lower headrace tunnel, discharge rate 2.0 m 3 /sec.Siphon spillwayAfterbay reservoir drawoff tunnelAccess tunnelPumping station suction shaft and conduit, ø 1.80 mConduit crossing under torrentTsidjiore-Nouve buried headrace tunnel, ø 0.80 mBuried discharge conduit, ø 1.65 m to 1.90 m130 kV lineSwitchyardAccommodation and canteenAccess cableway to main collectorRoadsHeliportMaya afterbay reservoir1N25164550 50 100m143610715H814119121312345678910Pumping station suction shaft and conduit, ø 1.80 mLow pressure control valveMachine hallOverhead travelling cranePumpTransformerHigh pressure control valveCable gallerySwitchyardBuried discharge conduit, ø 1.65 m to 1.90 mCross-section of station2 units each comprising:1 pump delivering 4.2 m 3 /sec, head 312 m,and 1 synchromotor, 16.2 MW1 unit comprising:2 half-pumps each delivering 2.1 m 3 /sec,head 312 m, and 1 synchromotor, 16.2 MWTotal station discharge rate: 12.6 m 3 /sec.4 8 93 5 7101260 5 10m

GD. P.42The real challenge:managing the waterDual requirementBuilding the collecting and pumping works to bring thewater of 35 Valais Canton glaciers to Lake Dix was hard,dangerous work. Building a gravity dam capable of resistingthe pressure of an artificial lake containing 400million m 3 of water was a titanic undertaking. But all theseefforts would be as nought if human beings were notable to manage this source of energy with meticulouscare.The real challenge lies in making the most of the <strong>Grande</strong><strong>Dixence</strong> scheme – in being able to find the best possiblematch between the scheme’s constraints, customerdemands and market prices.On paper, the requirements of <strong>Grande</strong> <strong>Dixence</strong> arestraightforward: Lake Dix must be filled with as muchwater as possible during the limited period when glaciersand snow melt. But in reality, this is a properheadache. The capacity of the large water conduit, whichmust never be put under pressure, is one factor to takeinto account; attention must also be paid to changesin the water intake discharge rate, the weather forecastsand the short, medium and long-term water supply mustbe monitored and the water caught at favourable timesin the neighbouring valleys must be pumped withoutforgetting the restitution of large quantities of water forecological, tourism and contractual reasons.The economic dimension of <strong>Grande</strong> <strong>Dixence</strong> is of coursea prime concern. The scheme is there to supply themarket with high-quality energy at peak hours. The storagelevel of the scheme must be optimized to ensuremaximum availability before the periods of high demand.In order to achieve a satisfactory organizational energybalance sheet, it is imperative to calculate continuouslythe cost of the energy consumed by the summer pumpingand the yield from the energy produced in winter.This dual requirement is essential to the profitabilityof the scheme. Only precise computer-aided managementis capable of taking account of the multitude ofparameters that change minute by minute. All the datacaptured in the thousand recesses of the <strong>Grande</strong><strong>Dixence</strong> system are transmitted to the WaterManagement Centre at Sion, which is equipped to adjustany part of the collecting and pumping equipmentat any time.The Sion Centre is a laboratory, equipped to predict allthe water supplies and flows that will be needed to fillthe dam-lakes. Here probes and the electronic chiptake their revenge on the concrete of the civil engineeringstructures. The remote control system gathers andtransmits continuously to Sion some 400 measurementsand 2500 signals. All the vital organs - pumps,valves, penstocks and main water conduit - are constantlymonitored and remotely controlled. Informationis transmitted in real-time using the high-voltage lines,beam power and fiber optics. Data are thus recordedand analysed day and night.Glacier melt parameters are still very complex. However,the statistics recorded over many years allow the resourcesto be managed optimally.The Water Management Centre is permanently connectedto meteorological services and the operatingpartners in order to be able to take all necessary decisionsat any time and in full possession of the facts.There is a great deal at stake with this method of highprecision management: a million cubic metres of waterlost means more than 4 million kWh less energy inthe winter.

GD. P.43Lake Dix

GD. P.44Behind the<strong>Grande</strong> <strong>Dixence</strong> wall…

GD. P.45

GD. P.46…the water of35 Valais glaciers awaits!

GD. P.47

GD. P.48Pendulum measuring pointSafetyMoment-by-moment monitoringManaging water means not only being capable of exploitingthe quintessential nature of its power. It is also,and above all, a matter of monitoring it, domesticatingit and controlling it to prevent accidents. Safety is theprime concern, the fundamental requirement that haspresided over the construction of the dam from beginningto end.The movements of the structure and the state of theneighbouring rock are continuously checked. The<strong>Grande</strong> <strong>Dixence</strong> dam is equipped with 32 kilometresof tunnels. These twisting, turning tunnels lead tothe measuring points, and especially to the 7 verticalpendulums that plunge down from the crest acrossthe entire depth of the wall and to the 3 inverted pendulumsthat check the dam and its foundations fordeformation.Surveillance is constant. Nothing is left to chance. Thereis geodesic and discharge rate measuring to monitorthe structure and detect the slightest weakness. Thedam has been designed to be strong enough to withstanda seismic shock of an intensity never recordedin Valais Canton.Today, technology and the advances of remote measurementhave considerably changed the life of thedam’s surveillance officers. Their regular patrols andobservations are simplified by the automated recordingand transmission of all the data to the Sion WaterManagement Centre.However, the simplest methods are sometimes themost effective. Throughout the valley, downstream fromthe dam, danger notices and audio alarms ensurethe safety of the local population should water suddenlybe released.One thing is certain: after more than 40 years ofoperation, the builders’ predictions have proved tobe remarkably accurate. The impermeable 200 metredeepgrout curtain has been effective beyond allexpectation. The total loss of water through lateralseepage is minimal. Barely a drop, given the size ofthis lake containing 400 million m 3 of water.Dam inspection galleries

GD. P.49

GD. P.50To be able to use the LakeDix water, one new andthree original powerstations are needed2000 hours of turbiningThe 400 million m 3 stored in the <strong>Grande</strong> <strong>Dixence</strong> storagereservoir represent a tremendous energy potential.They account for no more and no less than onefifth of all the stored energy in Switzerland.In order to ensure the profitability of the hydropowerconcentrated in Lake Dix, <strong>Grande</strong> <strong>Dixence</strong> turbines thewater in two stages. First, at an altitude of about 1490 mat the Fionnay plant. Second, by the Rhône, 1000 mlower down, at the Nendaz plant.The Fionnay and Nendaz power plants relay each other,helped by the EOS-owned Chandoline power station,in order to transform this mass of water into electricityand tame this quiet power into producing billions ofkWh of energy.These three power plants have an overall generatingcapacity of 800 MW. With the existing turbines, runningat full strength, it takes over 2000 hours to emptythe lake created by the <strong>Grande</strong> <strong>Dixence</strong> dam.

GD. P.51Fionnay power plant

GD. P.52Fionnaypower plant800 metres with a 73% gradient!To bring the water from the <strong>Grande</strong> <strong>Dixence</strong> dam tothe first turbines at the Fionnay power plant, a ninekilometerunderground tunnel had to be built and fittedout. This pressure tunnel slopes steeply: the averagegradient is about 10%. When it was driven through,the labourers and engineers were faced with seriousproblems due in particular to water seepage.Completely underground, the Fionnay plant has 6generating units, each equipped with 2 Pelton turbines,total capacity 320 MW. The head varies between 680 mand 874 m, depending on the level of water in the<strong>Grande</strong> <strong>Dixence</strong> dam.The surge tank is at the end of the Louvie tunnel, inBagnes valley; the tunnel then becomes a steel-linedshaft which plunges more than 800 m down a 73% incline!The shaft ends at the Fionnay power plant distributor,an enormous cavern hewn out of the rock.Fionnay Village

GD. P.5311161110179715131261815145481432N1123456789101112131415161718Louvie steel-lined penstock, ø 3.0 to ø 2.8 mValve chamberMachine hallTransformers and 220 kV equipmentOutside service buildingsPower plant tailrace canalTailrace spillwayPower plant access tunnelTailrace outlet in the reservoir and water intake for the Nendaz power plantNendaz tunnel guard gate, ø 3.0 mLa Dranse diversion, reservoir drawoff and spillwayForces Motrices de Mauvoisin (FMM) reservoir drawoff tunnelWater exchange tunnel between FMM and <strong>Grande</strong> <strong>Dixence</strong>Champsec power plant headrace tunnelPower plant winter access tunnelLouvie gate access cableway<strong>Grande</strong> <strong>Dixence</strong> afterbay reservoirFMM afterbay reservoir123456789Louvie steel-lined penstock, ø 3.0 to ø 2.8 mValve chamberMachine hallOverhead travelling craneTurbo-generating units15 kV switchgear15/220 kV transformer220 kV equipment220 kV lineCross-section of power plant6 horizontal units comprising:1 alternator and 2 Pelton turbinesTotal station discharge rate: 45 m 3 /sec.Gross head: max. 874 m; min. 680 mInstalled capacity: 6 x 60 MVA = 360 MVA3 blocks each with three 120 MVA single phasetransformers9412356 7 80 10 20m

GD. P.54Nendazpower plantThe biggest hydropower plantin Switzerland after BieudronThe waters of <strong>Grande</strong> <strong>Dixence</strong>, having been turbineda first time at the Fionnay plant in the Bagnes valley,dive back deep inside the rock. They cross the mountainagain in the direction of the neighbouring Nendazvalley.The precious water - the “white gold” - is again channelledinto a pressure tunnel that ends in the Pérouasurge tank, 1000 metres above the Nendaz generatingstation. This second power plant is just as discreteand invisible as the one at Fionnay, because it too ishidden inside the mountain. It lies between Aproz andRiddes, on the banks of the Rhône, 478 m. above sealevel.The tunnel linking Fionnay and Nendaz is 16 kilometreslong and ends in another steel-lined penstock.On the way, water from the Fara, originating in theIsérables Valley, is added to the flow heading towardsNendaz.The Nendaz generating station is the biggest hydropowerplant in Switzerland after Bieudron. It workson the cascade principle with the Fionnay station, i.e.its capacity and discharge rate are modulated in tandemwith Fionnay. Together, the two stations generatearound 2 billion kWh per year.The plant has 6 generating units each equipped with2 Pelton turbines, giving a total capacity of 430 MW.14542314914157111414N13812345678910111213141516Nendaz steel-lined shaft. ø 2.9 mValve chamberMachine hallTransformersGallery and gangway of the 220 kV cables of the first 3 sets220 kV cables of the last 3 setsTailrace canalTailrace canal partial bulkheadPower plant access tunnelRhône bridgeService building, workshop and entrance to power plantChamoson switchyard control buildingWorkshop and central depôtProtective fillFionnay-Chamoson 220 kV lineChamoson 220 kV switchyard5610 101216

GD. P.551234567Nendaz steel-lined penstock, ø 2.9 mValve chamberTailrace canalTurbo-generating unitsMachine hallOverhead travelling craneTransformersCross-section of power plant6 horizontal units comprising:1 alternator and 2 Pelton turbinesTotal station discharge rate: 45 m 3 /sec.Gross head: max. 1008 m; min. 1002 mInstalled power: 6x80 MVA = 480 MVA6x80 MVA three phase transformers61 52473

GD. P.56Cleuson-<strong>Dixence</strong> vital statisticsThe Cleuson-<strong>Dixence</strong> scheme was built entirely undergroundbetween 1993 and 1998. It comprises thefollowing main structures:■ New water intake built into the <strong>Grande</strong> <strong>Dixence</strong>dam at Le Chargeur.■ 15.8 km headrace tunnel between the dam andTracouet.■ Surge tank at Tracouet, carved out of the Dentde-Nendazmountainside.■ 4.3 km sloping steel-lined penstock, from Tracouetto the Bieudron powerhouse.■ Underground power plant equipped with 3 verticalturbine generators, each comprising a 423 MWPelton turbine and a 465 MVA alternator.Gross head: 1883 mDischarge rate: 75 m 3 /sec.Maximum generating capacity: 1200 MW(For comparison, the Gösgen nuclear plant has a capacityof 970 MW and the Leibstadt nuclear plant acapacity of 1165 MW)Costs (including finance charges): CHF 1.3 billionCleuson-<strong>Dixence</strong> complex:Output of a largenuclear power plantavailable in 3 minutesCapacity more than doubledThe main function of a hydropower plant is to copewith fluctuations in demand. When demand is at itshighest, for example on a winter morning betweeneleven and twelve a.m., the water retained behindthe dams is turbined to complement energy producedelsewhere in the country or in Europe by run-of-theriverpower plants and thermal or nuclear power plants.Production must equal consumption at any one time.Before Cleuson-<strong>Dixence</strong> was built, emptying Lake Dixrequired around 2000 hours of turbining, from Octoberonwards. With the new Bieudron power plant, it is possible,when operating at full capacity, to concentrateproduction over only 1000 hours.The available capacity has been multiplied by a factorof 2.5. With the current facilities at Fionnay, Nendazand Chandoline, the <strong>Grande</strong> <strong>Dixence</strong> complex has atotal capacity of 800 MW. Cleuson-<strong>Dixence</strong> enablesthis capacity to be increased by 1200 MW, thus givingthe complex a total capacity of 2000 MW.Like Fionnay and Nendaz, the main mission of Cleuson-<strong>Dixence</strong> is to supply power instantaneously, on demand.In barely 200 seconds, the facility is capableof injecting the equivalent of a nuclear power plant’stotal output into the grid!The energy produced by the whole <strong>Grande</strong> <strong>Dixence</strong> /Cleuson-<strong>Dixence</strong> facility is 2 billion kWh per year, or theannual average consumption of 400,000 households.

GD. P.57Bieudron power plant

GD. P.58

GD. P.59Extreme pressures!The penstock is the power enabler of the Cleuson-<strong>Dixence</strong> facility. The steel-lined shaft runs along the leftbank of the Rhône between the foot of the Dent-de-Nendaz mountain at 2150 m altitude and the Rhôneplain at 480 m, a difference of 1670 m over an inclineddistance of 4.3 km.A tragic accident caused the penstock to fail inDecember 2000. To restore the facility, a new steel tubewill be inserted into the existing shaft.Given the height of the dam, the static pressure is 190bars at the turbine inlet. 190 times atmospheric pressure!From the beginning of the construction work, theplan was to fully line the shaft and encase it in concrete.The tube is 3 m in diameter at the base of thestructure. The thickness of the lining is 6 cm.The accidentA geyser spouted from the earthThe first command governing the actions of the dambuilders and of those who built the power plants wasalways, and at all times, <strong>SA</strong>FETY. This constant concernto protect people and the environment translatedinto extremely high construction standards. Unfortunately,despite every effort, every calculation, it is not alwayspossible to tame the savage power of nature and water.On 12 December 2000, shortly after 20.00 hrs, thepenstock bringing water from the <strong>Grande</strong> <strong>Dixence</strong> damto the Bieudron power plant ruptured between Pérouaand Condémines at a height of 1234 m. Despite thespeed with which the scheme’s safety systems cameinto operation, a large volume of water spouted up,like a geyser, and hurtled down the mountainside, atorrent of mud and rock. This moving mass took everythingwith it and devastated everything in its path: trees,orchards, barns, chalets… Three people were buried.The Sion - Riddes road on the left bank of the Rhônewas cut off by the rockfall. The Rhône itself was blockedfor a short while.Since then, the Bieudron power plant has been at astandstill and its 1200 MW capacity lies dormant.Having studied the causes of this accident at length,it was determined that the way the welds were donecaused the steel-lined shaft to fail.2005 was the year when the initial work to restoreCleuson-<strong>Dixence</strong> began. The entire section will berepaired by lining the existing shaft. This means that anew steel tube will be inserted inside the original conduit.In the accident area, the ruptured part of the penstockhas been abandoned. The chosen solution is to builda deep bypass. If everything runs to plan, Cleuson-<strong>Dixence</strong> will be brought back into service by the endof 2009.

GD. P.60The challengesof hydropowerInstant response to demandThe miracle is still there but no-one pays attention toit any more. No-one thinks about the technologicalprowess that enables a switch to be activated by justa click, so lighting a room or powering up a televisionset. Are consumers at all aware that power from theFionnay and Nendaz plants is injected on the transmissiongrid at their demand?In Switzerland, basic electricity is provided by nuclearenergy, which covers 40% of the total consumption.Run-of-the-river power plants supply 25% of the requirements.Some conventional thermal power plantsstill account for 4 to 5%. The remainder, almost onethird of consumption, is covered by stored energy plants(hydro). Clearly a much higher proportion than ourneighbours, who are more reliant on nuclear and fossilenergy.Because electricity cannot be stored, except in verysmall quantities, the hydropower plants play an essentialrole. They are the only generating plants capableof injecting considerable power into the grid within afew minutes. They are also the only plants able to holdin reserve the energy surpluses needed to meet a demandthat varies from hour to hour, from day to day,from season to season.The dams are the only “canned” variety of electricity.Production occurs only on demand, and there are noenvironmentally harmful emissions. This green energyis a security for future generations.Electricity generation in Switzerland – 2004Contribution of the different types of plantsIt was to cope with the increasing demand of consumersthat dams like <strong>Grande</strong> <strong>Dixence</strong> were built.Although basic consumption is met by the electricitygenerated by nuclear and run-of-the-river power plants,the storage dams supply a reserve of energy that isdelivered on demand.30%40%The <strong>Grande</strong> <strong>Dixence</strong> version of the hydropower missionis therefore to cover consumption peaks. Theyoccur in winter, mainly between January and March,and especially on weekdays between eight in themorning and eight in the evening, when there is thehighest concentration of human activity. Maximumpeaks are generally reached at mealtimes.4,7%25,3%Nuclear power plantsHydropower plants (stored water)Run-of-the-river power plantsConventional thermal power plants

GD. P.61

GD. P.62A senseof balanceThe Dispatching Centre (CEG)All those involved in supplying electric energy are veryaware of one thing: their job is akin to that of a tightropewalker. Absolutely dependent on consumer demandand the whims of the weather, completely caught byproduction constraints and grid congestion, needingto pay attention to many other factors, energy suppliersand distributors must juggle with an essential rule,a basic axiom: at any one moment, the electricity generatedmust equal the electricity consumed. So everykWh must be produced at the precise moment it isconsumed!To enable it to perform its task properly, EOS has aDispatching Centre (CEG or Centre d’Exploitation etde Gestion). From there, EOS manages and coordinatesits electricity generating fleet in real time, in closecooperation with the <strong>Grande</strong> <strong>Dixence</strong> Water ManagementCentre at Sion. This control centre is the brainof the operation. It enables generation management,transmission operation, energy exchanges and theconstant balancing of the electricity grid to be controlled24 hours a day, 365 days a year.EOS (Energie Ouest Suisse) has been mandated bythe shareholders of <strong>Grande</strong> <strong>Dixence</strong> to manage theenergy flows produced by the <strong>Grande</strong> <strong>Dixence</strong> complexwith a view to maintaining the flexibility of thescheme in the best possible way.

GD. P.63

GD. P.64The CEG enables a large number of operations to beremotely controlled at all times. Its remit covers all aspectsof the energy chain.Generation: the CEG supervises and controls the powerplants. The start-up, shutdown and loading of the generatingunits are remotely controlled from Lausanne.Transmission: once generated, the electricity must berouted to the distributor or the consumer, via very highand high voltage networks. Operating, supervising andremotely controlling the network are key tasks. Themanagement of the transmission network also impliesan ability to respond instantaneously to the slightestincident (overload, overvoltage, activation of alarms,equipment alerts etc).Control area: the CEG must ensure a balance at alltimes between what is produced or received over thegrid and what customers need. Because electricitycannot be stored, this means checking that the quantityof energy produced always matches the quantityconsumed.Sales: each shareholder of <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong> managesthe commercialization of its share of the electricitygenerated by <strong>Grande</strong> <strong>Dixence</strong>. Using the tremendousasset constituted by the flexibility of the storage dams,it gives instructions each day about the use to be madeof the generating stations, as a function of demandand the price of electricity.

GD. P.65CEGElectricity prices vary enormously during the year. Ingeneral, they are lower in summer than in winter. Theyare highest during peak periods of consumption.Many factors account for these fluctuations, mainly:■ Changes in primary energy prices (oil, gas, coal).■ Production costs of the latest power plants to bebrought into service to meet demand.■ Meteorological conditions (very cold and very hotweather pushes prices up).■ Stored water reserves, which vary from year to year.In the longer term, other factors will also influence electricityprices. Constantly rising demand and reducingreserve capacity everywhere in Europe will play a fundamentalrole, as will the increasing problems of congestiongiven the notable lack of cross-border transmission capacity.Other unknowns will also have an influence. Howfar will the markets open up in fact? Are we moving towardsgeneral liberalization or oligopolisation?It can only be said that setting electricity prices has becomea complex matter. Surviving in this uncertainworld means being flexible. More than ever it is betterto be a very good… tightrope walker.

GD. P.66The <strong>Grande</strong> <strong>Dixence</strong>scheme: in the heartof a pristine setting

GD. P.67

GD. P.68The environment:a constant concernThe future belongs to white gold and green energyWhat a paradox! Self-sufficient for so long, and evenan exporter of electricity, Switzerland is poised to becomea net importer of electricity.Under these circumstances, with energy becomingrarer and fears about global warming, hydropower ismore than ever a form of energy that should be givenpriority.Those who initiated the <strong>Grande</strong> <strong>Dixence</strong> constructionproject were always aware of this. Could there everbe a finer source of environmentally-friendly energy!But apart from the fact that this is a clean and renewablesource of electricity, the design engineers paidparticular attention to the environment. In the 1950s,ecology may not yet have been a core concern, butthose who built <strong>Grande</strong> <strong>Dixence</strong> were ahead of theirtime when it came to mountain conservation. Theirconstant endeavour was to preserve the natural environment,to blend completely into the grandiose Alpinesetting. Water pipes, power plants, pumping stations,everything that could be hidden away beneath the surface,was buried. The earthworks were returned to theirnatural state.Nonetheless, energy production, transmission andconsumption are not neutral for the environment. Evenif the energy comes from a renewable source, as hydropowerdoes, with no release of greenhouse gases intothe atmosphere, great care must be taken all along thechain of activity that leads from a drop of water to theelectron that is supplied to the electric power socket.The design, realization and operation of structures andfacilities are consequently the subject of detailed attention.Safety and respect for the environment, a majorpriority everywhere and at every moment, can thusbe ensured.Aware of the value of the environment, <strong>Grande</strong> <strong>Dixence</strong>has chosen to maintain and improve its generatingequipment and structures in order to optimize the useof the natural resource. To that end, it has a numberof committments, including:Respect for the legal requirements, and for the termsof the concessions and permits.Ensuring that operations are carried out in a waythat limits as far as possible the impacts on watercourses and their ecosystems (flushing operations,etc.) and preventing pollution.Minimizing the impact on the landscape caused bythe carrying out of civil engineering works.Maintaining a constructive dialogue with partners,the public and communities affected by the facilities.Promoting cooperation with service providers andsuppliers that have a concern for the environment.Constantly improving its environmental performancethrough action programmes.As a result, an environmental management system wasestablished in <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong> in 2000. In 2001, theefforts were rewarded by ISO 14001 certification.Furthermore, the electricity produced by <strong>Grande</strong><strong>Dixence</strong> has been awarded the TÜV EE 002 (April 2000)and naturemade basic (January 2002) energy qualitylabels.In July 2003, the operation of the <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>hydropower generation facilities was entrusted to anew company, HYDRO Exploitation <strong>SA</strong>, founded a yearearlier. This new company has made respect for theenvironment one of its priorities from the start. On 4July 2004, it obtained triple certification for Quality, theEnvironment, and Health/Safety.

GD. P.69

GD. P.70<strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>financial interestsElektrizitätswerk Zermatt AG (EWZ), industrialservices for the municipality of Zermatt, with 45% ofthe share capital held since November 2001. Thispartnership has allowed EWZ and <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>to develop synergies to exploit and process thewater in the Zermatt basin.HYDRO Exploitation <strong>SA</strong>, created in June 2002 jointlyby EOS Holding and FMV <strong>SA</strong>, to manage their installations.<strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong> holds 36.8% of the sharecapital. Established in 2003, HYDRO Exploitation <strong>SA</strong>was one of the first companies to focus entirely on theuse of hydroelectric energy. Primarily designed for itsshareholders, the company's services could also beoffered to the owners of other hydraulic facilities inValais or elsewhere.Cleuson-<strong>Dixence</strong>, an ordinary partnership createdjointly with EOS in 1992 to increase the capacity forelectricity production. <strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>'s holdingis 15/22.Forces Motrices de la Borgne <strong>SA</strong> (FMdB), with 29%of the share capital since January 2009. FMdB ownsthe Bramois development, located upstream ofthe <strong>Grande</strong> <strong>Dixence</strong> installations, and uses the watersof the Borgne river. FMdB's other shareholders arethe communes of Hérémence, Mase, Nax, Sion,St-Martin, Vernamiège and Vex (51%) and the companyFMV <strong>SA</strong> (20%).<strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>shareholders60%Alpiq Suisse <strong>SA</strong>, LausanneAxpo AG, BadenBKW FMB Participations <strong>SA</strong>, Bern13 1/3%13 1/3%13 1/3%IWB Industrielle Werke Basel, Basel

GD. P.711 kWh1 MWh1 GWh1 TWhUNITS OF ENERGY= 1 Kilowatthour = 3600 Kilojoules [kJ]= 1 Megawatthour = 1000 kWh = 3 600 000 Kilojoules [kJ]= 1 Gigawatthour = 1 million kWh = 3.6 Terajoules [TJ]= 1 Terawatthour = 1 billion kWh = 3600 Terajoules [TJ]1 kW1 MWUNITS OF POWER= 1 Kilowatt = 1000 Watts [W]= 1 Megawatt = 1000 Kilowatts1 kVUNIT OF VOLTAGE= 1 Kilovolt = 1000 Volts [V]1 kVA1 MVATRANSFORMATION CAPACITY= 1 Kilovoltampere= 1 MegavoltampereGraphic design and photos:essencedesignMédiathèque Valais-Martigny photos:Frank Gygli 6-7, 13, 14Unknown 8<strong>Grande</strong> <strong>Dixence</strong> 11, 15, 24Henri Germond 12, 13, 17 (left), 23, 24-25Charles Paris16, 19, 20, 24 (bottom left)Jacques Thévoz17 (right)Joseph Couchepin 18Heinz Preisig 48Text:Jean Luqué / EOS – <strong>Grande</strong> <strong>Dixence</strong>

Further details from:<strong>Grande</strong> <strong>Dixence</strong> <strong>SA</strong>, Sion 027 328 43 11 www.grande-dixence.chdesign: essence.ch