Misc

What is the FIFA World Cup Trophy Made Of?

What is the FIFA World Cup Trophy Made Of?

Soccer is one of the world’s most popular sports with approximately 3.5 billion fans globally.

It was in Uruguay, in 1930, that the very first FIFA World Cup was held. It has occurred once every four years since then (except in 1942 and 1946 due to World War II).

This year, 92 years after its start, the 22nd FIFA World Cup tournament is scheduled to take place in Qatar. The highly anticipated event involves 32 national teams that will compete to win one of the most prestigious titles and a historic trophy.

So, what is the coveted FIFA World Cup trophy made up of?

The History and Composition of FIFA World Cup Trophies

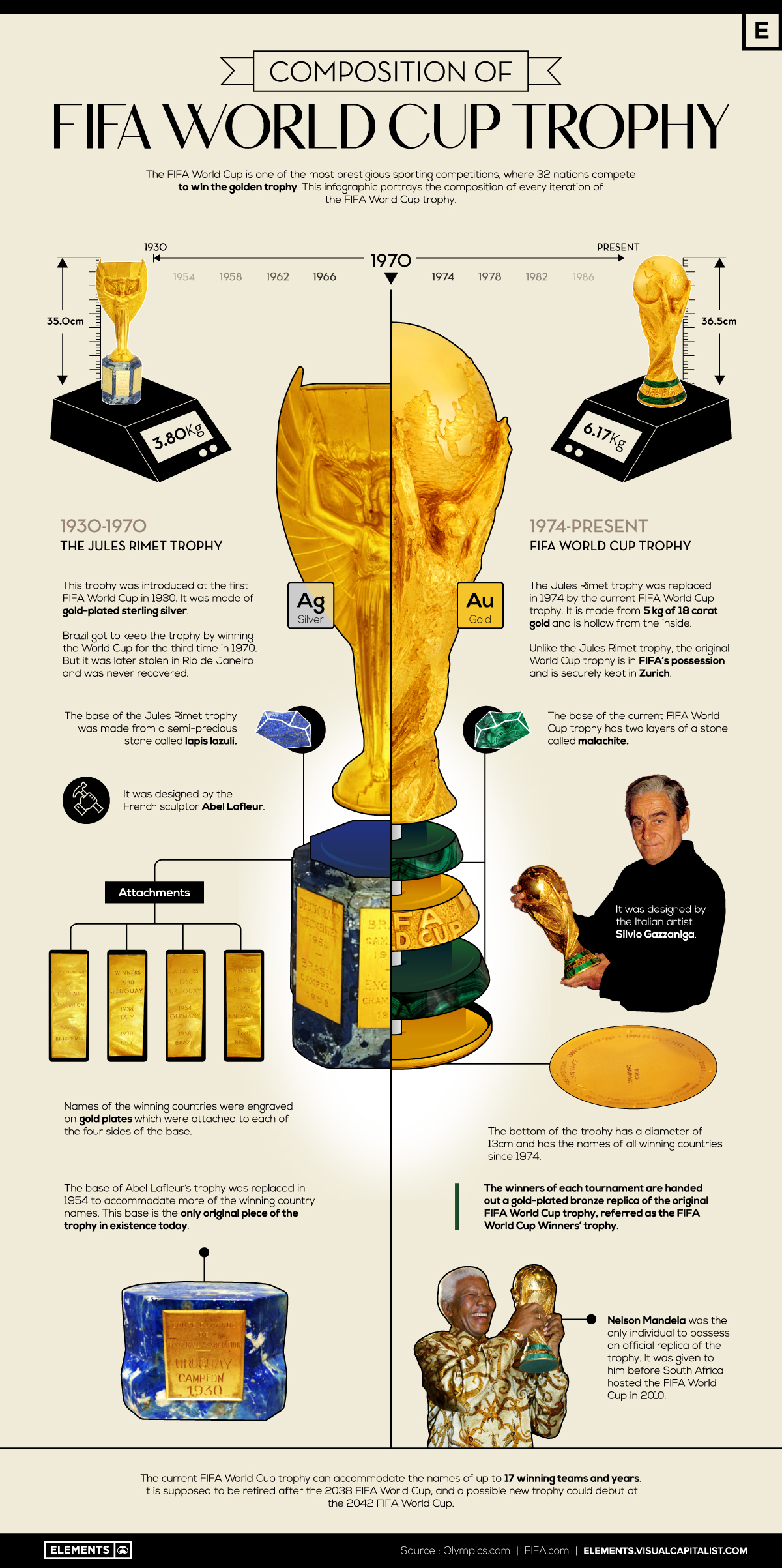

Since its debut in the first FIFA World Cup tournament, in 1930, there have been two iterations of the World Cup trophy. Both trophies were made with a combination of metals and rare stones.

Until 1970, the Jules Rimet Trophy, designed by the French sculptor Abel Lafleur, glorified the winning team. A redesigned version of the trophy by Silvio Gazzaniga replaced the original in the 1974 FIFA World Cup tournament.

The Jules Rimet Trophy

Commonly called the Coupe du Monde (French for World Cup), the Jules Rimet trophy was officially renamed in 1946, honoring the then FIFA president Jules Rimet on his 25th Anniversary in office.

The trophy had a height of 35cm and weighed 3.8kg. It was made of gold-plated sterling silver and featured Nike, the Greek Goddess of Victory, holding an octagonal cup. The base of the trophy was made from a semi-precious stone called lapis lazuli. Golden plates were attached to each side of the base and they held the names of the winning teams from 1930 to 1970.

Since the beginning, it was agreed that the first team to win the World Cup three times would get to permanently keep the trophy. In 1970, Brazil marked its third victory by beating Italy in the finals and took the Jules Rimet trophy home.

However, in 1983, the trophy that even survived World War 2 was stolen from the Brazilian Football Confederation (CBF) headquarters in Rio de Janeiro and was never found. The only original piece of the Jules Rimet trophy in existence is the base that was replaced in 1954 to accommodate more winning-team names.

The FIFA World Cup Trophy

After handing over Abel Lafleur’s original trophy to Brazil in 1970, FIFA held a design competition in search of a new World Cup trophy. The association received 53 submissions from seven countries and Silvio Gazzaniga’s design of two human figures holding the Earth in their hands won the competition.

This new trophy is 36.5cm tall and weighs 6.17kg. It is made from 5kg of 18-karat gold and two layers of malachite. The base of the trophy is 13cm in diameter and the names of all winning teams since 1974 along with the years are engraved on it. This current iteration of the World Cup trophy can accommodate the names of 17 winning countries and years.

Unlike the Jules Rimet trophy, the current iteration of the trophy will not be handed over to a team definitively. It permanently belongs to the International Federation of Association Football (FIFA) and is secured at its Zurich headquarters.

However, a gold-plated bronze replica of the cup referred to as the World Cup Winners’ Trophy is given to every winning team.

Battle Royal: The 2022 FIFA World Cup

The 2022 FIFA World Cup tournament is long awaited by billions of passionate soccer fans.

It could be the final opportunity for two of the world’s best players—Cristiano Ronaldo, and Lionel Messi—to lift the World Cup trophy as they supposedly plan to retire from international games before the next World Cup.

This year, will your favorite national team be able to pose for a victory picture holding the golden trophy in their hands?

Misc

Visualizing Global Aluminum Production

China dominates global production with nearly 60% share.

Visualizing Global Aluminum Production

This was originally posted on our Voronoi app. Download the app for free on iOS or Android and discover incredible data-driven charts from a variety of trusted sources.

This infographic shows estimated aluminum smelter production by country in 2023, based on data from the most recent U.S. Geological Survey (USGS) Mineral Commodity Summaries, published in January 2024 .

From this data, we can see that China leads as the top producer, accounting for nearly 60% of the world’s smelter capacity. Its neighbor India is the second-largest producer, making only a tenth of China’s output.

| Country | 2023 Aluminum Smelter Production (tonnes) | % of total |

|---|---|---|

| 🇨🇳 China | 41,000,000 | 59% |

| 🇮🇳 India | 4,100,000 | 6% |

| 🇷🇺 Russia | 3,800,000 | 5% |

| 🇨🇦 Canada | 3,000,000 | 4% |

| 🇦🇪 United Arab Emirates | 2,700,000 | 4% |

| 🇧🇭 Bahrain | 1,600,000 | 2% |

| 🇦🇺 Australia | 1,500,000 | 2% |

| 🇳🇴 Norway | 1,300,000 | 2% |

| 🇧🇷 Brazil | 1,100,000 | 2% |

| 🌍 Rest of the World | 9,460,000 | 14% |

| Total | 69,560,000 | 100% |

Responsible for 5% of global aluminum output, Russia has been targeted by recent sanctions from the U.S. and the UK.

The sanctions include prohibiting metal-trading exchanges from accepting new aluminum produced by Russia and barring the import of the Russian metal into the U.S. and Britain. The actions are aimed at disrupting Russian export revenue amid Moscow’s ongoing invasion of Ukraine.

The World’s Most Common Metal

Aluminum is the primary material used for making cans, foil, and many other products. It originates from bauxites, rocks composed of aluminum oxides, and various minerals.

Approximately 25% of annually produced aluminum is utilized by the construction industry, while another 23% is allocated to vehicle frames, wires, wheels, and other components within the transportation sector. Aluminum foil, cans, and packaging constitute another significant end-use category, accounting for 17% of consumption.

Despite its extensive use, aluminum is still plentiful. Aluminum is the world’s most common metal by crustal abundance, making up 8.2% of the Earth’s crust.

According to the USGS, global resources of bauxite are estimated to be between 55 billion and 75 billion tonnes and are sufficient to meet world demand for metal well into the future.

Misc

Brass Rods: The Sustainable Choice

Brass rods can help cut emissions in machine shops, be recycled without losing properties, and contribute to a cleaner environment.

Brass Rods: The Sustainable Choice

Brass rods have a powerful lineup of green attributes, making them the sustainable choice for manufacturers and end-users of precision machined and forged parts.

This infographic, from the Copper Development Association, shows how brass rods can reduce emissions in machine shops, be recycled without losing properties, and contribute to a cleaner environment.

The Brass Rod Circular Economy

The metallurgical properties of brass allow pre- and post-consumer sources of brass scrap to be recycled with no loss in properties.

Brass scrap can retain over 90% of the original material value. In addition, brass doesn’t need energy-intensive processing, unlike steel and aluminum, which must be smelted and refined before being recycled into new products.

As a result, there is a greater chance that steel and aluminum scrap will end up in landfills.

Most brass-rod alloys produced in North America contain 95% or higher recycled content.

Closed-loop recycling of brass keeps this valuable engineering material out of landfills, reducing the need for new mines and all the environmental impacts that entails.

Higher Machinability Leads to Lower Operational Carbon Emissions

Machinability is how easily a material can be worked using cutting processes. It directly impacts the amount of energy required to produce finished parts.

With typical machine shops producing millions of parts each year, the carbon impact can be significant.

Here’s how brass and steel compare when manufacturing complex parts using computer numerical control (CNC) machining.

| Material | Brass | Steel |

|---|---|---|

| Type | Free-cutting brass (C36000) | Free-cutting steel (12L14) |

| Maximum machinability rating (0-100) | 100 | 21 |

| Metal Removal Rate (cubic inches per minute) | 0.238 | 0.114 |

| Time to remove material (hours) | 161,111 | 336,111 |

| Energy required to produce parts (kilowatt-hour) | 9,475 | 18,931 |

In this example, using brass represented a savings of 3,510 kg in carbon dioxide (CO2).

The significantly longer tool life enabled by brass also reduces the need for new cutting tools, further decreasing emissions.

High recycled content and exceptional machinability make brass rods the sustainable choice for manufacturers and end-users seeking to reduce their environmental footprint and support the transition to a low-carbon future.

Explore the advantages of brass rod solutions.

-

Electrification3 years ago

Electrification3 years agoRanked: The Top 10 EV Battery Manufacturers

-

Electrification2 years ago

Electrification2 years agoThe Key Minerals in an EV Battery

-

Real Assets3 years ago

Real Assets3 years agoThe World’s Top 10 Gold Mining Companies

-

Misc3 years ago

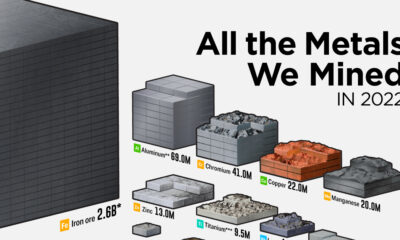

Misc3 years agoAll the Metals We Mined in One Visualization

-

Energy Shift2 years ago

Energy Shift2 years agoWhat Are the Five Major Types of Renewable Energy?

-

Electrification2 years ago

Electrification2 years agoMapped: Solar Power by Country in 2021

-

Electrification2 years ago

Electrification2 years agoThe World’s Largest Nickel Mining Companies

-

Misc3 years ago

Misc3 years agoThe Largest Copper Mines in the World by Capacity